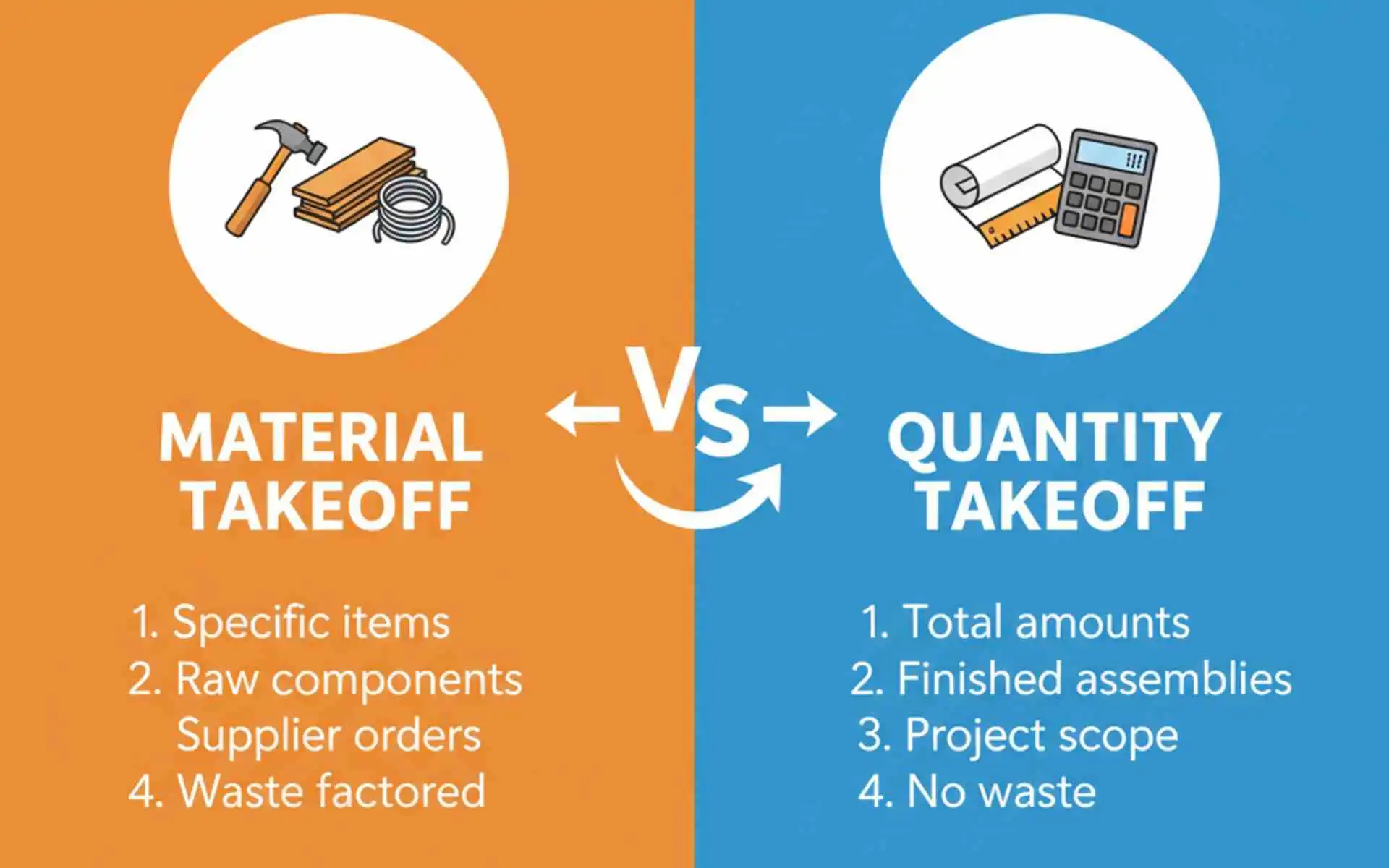

Material Takeoff vs Quantity Takeoff: Key Differences For Accurate Bids

Understanding Material Takeoff vs Quantity Takeoff in construction is paramount if you are involved in construction. Although these terms appear similar, that is not entirely the case. These two processes represent two completely distinctive purposes. Despite their differences, both of them are crucial for planning a project, preparing a budget, and ultimately for accurate bidding.

GET THE COMPREHENSIVE PICTURE OF MATERIAL AND QUANTITY TAKEOFF WITH US TODAY!

This article will help you understand the roles of both material and quantity takeoff. We will also discuss how these two differ from each other, as well as when these two are used.

So, stay with us and read this article for a comprehensive understanding.

Material Takeoff – A Procedure Solely for Construction Materials

In construction, this process is associated only with materials. This process is used to identify, list, and quantify the materials essential for any project. In short, the purpose of MTO is to assess what type of materials are required and how much

As mentioned above, MTO encompasses the takeoff services for the basic construction materials. For example, concrete, steel, metal, drywall, lumber, etc, and does not involve any other resources.

Primary Constituents of MTO

- Its primary focus is on estimating the cost of materials required for a construction project.

- Unit-based measurements are used to quantify how much material is needed, such as per square foot, cubic foot, or linear meter.

- The more accurate a material takeoff is, the more budget control you will have. Thus, preventing any over- or under-ordering.

Furthermore, in construction estimation, MTO is a crucial part. From a materials perspective, it will help contractors to prepare accurate and winning bids. In 2025, with more projects transitioning to digital workflows, many contractors now integrate Building Information Modeling (BIM) tools directly with MTO software for enhanced precision and real-time material tracking.

Construction Estimating Software in Material Takeoff

Construction Material Takeoff Services, utilize construction estimating software is a necessity. Otherwise, the process becomes more time-consuming and resource-intensive. In the past, manual spreadsheets were widely used, but they are now largely outdated due to inefficiency and high error potential.

As of 2025, leading software platforms use AI-driven automation and cloud integration for more precise takeoffs and save up to 40% in project estimation time.

Top-tier software includes:

- On-Screen Takeoff

- Trimble

- Fast Duct Estimating

- Fast Pipe

- Autodesk Takeoff

There you have it, a detailed description of MTO and what it encompasses. The discussion ahead is about Quantity Takeoff. So, let’s delve right into it!

Quantity Takeoff – Overall Resource Management

Encompassing all the resources that are involved in a construction project, quantity takeoff estimates all the resources in construction. From material, labor, to equipment and overheads. It can be said that it is a broader term that includes the quantity calculation and estimation of resources needed to successfully execute a project.

What QTO Necessitates?

- It provides an all-inclusive view of a project. Providing a contractor with a full picture of not only materials, but also labor, equipment, and how much time is needed.

- It breaks down a project into detailed and manageable components.

- The cost estimation process becomes more holistic in QTO. Because it will help in determining not only the amount but also the cost of resources.

- As QTO is a broader term that includes all the resources, it is then used for scheduling and planning of a construction project.

In recent years, QTO has evolved to integrate with cost databases and market trend analytics, allowing estimators to adjust prices in real time according to material or labor fluctuations.

Adoption of Construction Estimating Software and How it Helps

Any Estimating Company that wants to achieve maximum accuracy in its quantity takeoffs uses advanced estimating software. They not only help with takeoff services, but also greatly aid in bid preparation tasks.

Such software is as follows:

- PlanSwift

- Bluebeam

- Stack

- Quest Estimating

- RFMS

- RS Means

- ProEst

Now that you have fully apprehended both MTO and QTO, let’s explore the key distinctions between these two.

Key Difference between Quantity Takeoff and Material Takeoff

The most standout differences between Quantity Takeoff and Material Takeoff are as follows:

| Aspect | Material Takeoff (MTO) | Quantity Takeoff (QTO) |

| Objective | Calculates only the materials required for a project. | Includes all resources, materials, labor, equipment, and overheads. |

| Extent | Limited to estimating the cost of required materials. | Comprehensive estimation of all project resources. |

| Aim | Focused solely on material budgeting and procurement. | Involves full project scheduling and resource planning. |

| Level of Detail | Measures physical material quantities (e.g., concrete, steel, lumber). | Covers material quantities plus labor hours, and equipment usage. |

| Who Performs It | Material estimators and contractors. | Quantity surveyors or project managers. |

In 2025, many firms use a hybrid workflow where MTO and QTO data are synchronized through cloud-based estimating systems, ensuring accuracy and eliminating double entry.

Material Takeoff and Quantity Takeoff – Collective Effort for Accurate Bidding

- Where QTO identifies all cost drivers, material takeoff provides you with the specific pricing data only for the required materials.

- As MTO only focuses on materials, waste management is more efficient, thus leading to more realistic material quantities.

- From the materials perspective, MTO assures that the budget is not exceeded from what has been allocated

- A contractor can utilize the maximum potential of QTO to estimate the required labor and their hours for accurate bid preparation.

Together, MTO and QTO form the basis for cost effectiveness, for clear projects, both being crucial features highlighted by construction data management industry norms such as ISO 19650.

WANT A BID WITH ENHANCED CHANCES OF WINNING? CONTACT US AND GET THE BEST POSSIBLE SERVICES TODAY!

Ending Remarks

In the end, it is notably clear that Material Takeoff vs Quantity Takeoff are not the same. Each of them serves different purposes, but both are essential if you want your estimates to be accurate. By understanding these two, you can improve the prospect of accuracy right from the start. Lastly, by using these two together, you can manage a construction project more efficiently, and on top of that, your bid preparation becomes relatively easier, and chances of approval will increase exponentially.