Why is mechanical cost estimation important in project planning?

As a contractor or project manager, you must understand why Mechanical Cost Estimating is important in project planning. Most of the contractors underestimate this step before starting the project. In the initial phases of any type of building, whether residential, commercial, or industrial. Cost estimating all the mechanical things of the building should be a top priority. Because mechanical, electrical, and plumbing systems are the kernel of any building. Without their proper installation and the right choice of systems. The building can never function properly and the occupants will never feel cozy and safe in such an environment. That is why it is always emphasized to estimate the cost accurately.

The construction industry of the US is huge and contemporary. This competition has underlined the enormous importance of being unique. Multiple estimating companies are currently working to assist clients in having spot-on accuracy with their methods. This helps them to complete the project with a full guide. In the end, the project is completed successfully within the allocated budget and time. With the help of these professional companies, you get a chance to have the Best Mechanical Estimates. There is a huge responsibility on a contractor to complete the project within budget. That is why outsourcing cost estimating needs is the best decision nowadays!

In this article, you will get to know why mechanical cost estimation is important. Keep reading the guide and get the insights! If you are stuck in the mechanical estimation process and need assistance from any expert. Do not hesitate to contact a reputable company. You can take huge benefits from the Affordable MEP Estimator and move on with the project on the right track. You can easily search companies online and check the client’s feedback. Enlist multiple companies and then select the perfect one for your job. This will give you a guarantee of achieving the exact cost estimates.

Call us at (737) 843-4434

Fastest Turnaround 24-48 Hours

How Mechanical Cost Estimation Works?

Project Scope

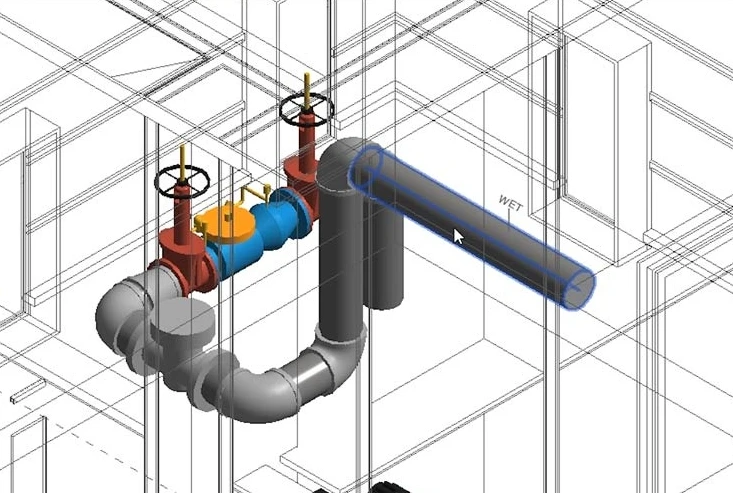

Mechanical Cost Estimation starts with the process of analyzing all the project details. Estimators and quantity surveyors read all the project documents and study drawings. This helps to know what are the requirements of the project. They consider all the factors like building size, occupancy, and local codes.

Material and Equipment Selection

Then estimators select the most suitable materials and equipment for the mechanical system. They match the prices and adjust them according to the project budget. Which factors are checked for exact mechanical cost estimation? They check three things: Efficiency, capacity, and durability.

Labor Costs

The labor cost required for all the mechanical work is estimated. It depends on the installation needs of the project. Some jobs on the site need more skilled labor such as plumbers, HVAC technicians, and electricians. These laborers require higher wages that increase the overall cost of the project.

Subcontractor Costs

Estimators also include the cost of subcontractors that are added to some kind of mechanical work of the project. So, they also add their cost in the estimation process.

Overhead and Profit

It is very important to include administrative expenses and insurance in cost estimates. These are considered to be the overhead costs. Additionally, the profit margin is also calculated and added to the EXEL sheets. This comprehensive addition of different costs makes sure to prevent budget overruns.

Contingency

It is a must to include a contingency amount in cost estimation. There is always a possibility of unforeseen circumstances or changes in the project. Mechanical engineers keep everything into account and do not forget to neglect any risk factors.

Final Estimate

In the final step, estimators compile mechanical cost estimation and recheck the estimates. They make sure before submission that everything is on point. If they find any error they refine them again and again.

Review and Adjust

They submit the proposal of mechanical cost estimation to clients in the form of EXCEL sheets. After receiving the client’s feedback, they adjust the estimates accordingly. By following these steps for the mechanical cost estimation process, they deliver detailed and accurate estimation.

Which Mechanical Materials are Quantified?

- Air devices

- Air handling units

- Air-cooled condensing units

- Air conditioning units

- Louver

- Hangers

- Boilers

- Heat pumps

- Exhaust fans

- Manual volume damper

- Rooftop units

- Dust smoke detector

- Pump

- Water heaters

- Chillers

- Backdraft damper

- Gas pipes

- Vent pipes

- Refrigerate pipes

- Condensate drain pipes

- Air cleaners

- Steam systems

- Air filters

- Pipe fittings

- Sheet metal ducts

- Duct fittings

- Thermostat

- Duct insulation

- Duct supports

- Humidifiers

- Ducts

Tips for Mechanical Cost Estimation

- Just make sure that the budget aligns with the project’s needs. The low estimate may look attractive at first but it leads to multiple problems. Just adjust the cost according to the resources needed for the project.

- Include the extra expenses in the estimation process. This will prevent delays.

- Work hard and spend enough time on the estimation process. Rush estimates are prone to errors and they may miss crucial information.

- You can use past successful projects as your reference point. Consider all the things in the scope and resources for the current project.

- Break down the project into smaller chunks to take things step by step. This will help you to make the process easy and fast.

READY TO TACKLE THE CHALLENGES OF RESIDENTIAL CONSTRUCTION ESTIMATING? CONTACT US TODAY FOR EXPERT GUIDANCE AND SOLUTIONS TAILORED TO YOUR PROJECT’S NEEDS!

Call us at (737) 843-4434

Fastest Turnaround 24-48 Hours

Conclusion

To be a pro in cost estimation, you need to invest a lot of time and effort. Your hard work will pay off later in the form of accurate price escalation. To become proficient in this work, it seems easy but it is a tough job. Because owners and project managers rely on estimators to complete the project within budget. If you are dedicated and serious about the work, you can help win bids. Those who want to start this work can start practicing and learning how to use estimating software. This software provides reliable solutions to simplify the estimation process and enhance the accuracy.