How to Estimate Gas Plumbing Costs for New Construction Project

In this article, we have discussed all the factors that may affect gas plumbing costs for new construction. If you are a newbie or you are having a problem evaluating the cost, you can rely on professional plumbing estimating services.

READ OUR ARTICLE TO SEE HOW TO ESTIMATE GAS PLUMBING COSTS FOR NEW CONSTRUCTION TO COMPLETE THE PROJECT WITHIN BUDGET AND TIMELINES AND DISCOVER WHY ACCURACY MATTERS THE MOST IN ESTIMATION!

Follow the Guidelines to Estimate Gas Plumbing Costs!

1. Initial Planning Must Be Perfect!

The gas plumbing projects are unique from every other project, and it starts with a detailed initial site assessment. This helps in planning the project perfectly in the starting phase of the project. First, you need to understand the property layout and what the distance to existing gas means, because it may affect the installation process.

Also, consider environmental regulations and local permit requirements early, as they can delay the project and affect overall costs.

2. Materials: Pipe Type and Costs

When budgeting for a new gas line system, choosing the most appropriate piping material is important to prevent budget overruns. In addition to that, the prices of materials fluctuate daily, which is why you have to be perfect while estimating. The most common materials for gas plumbing systems are:

-

The most common one is black iron, which is doable and preferred for the gas lines but it is labor-intensive due to the requirements. Typically, its costs range between $10–$15 per linear foot.

-

The second one is corrugated stainless steel tubing (CSST), which is flexible, easy to install, and requires less labor.

-

The third one is copper, which is less common for gas, but it is corrosion-resistant and used for specific purposes.

3. Labor Costs and Complexity of Installation

To calculate plumbing labor cost accurately, you need to factor in the complexity of the installation. Gas line work is generally more expensive than water plumbing due to the specialized skills and strict safety measures involved. Labor rates typically range from $75–$150 per hour. Keep in mind that complex routing, such as installing gas lines through tight or irregular spaces, requires more time and skilled professionals, which drives costs higher.

4. Consider All Requirements of the Job!

The most important crucial factor is to size gas pipes to ensure the safety and the flow of all appliances. You have to look into the BTU requirements and the distance of piping runs. If you’re going to install larger systems, then you may need multiple appliances, for example, wider pipes. However, all these factors combine to increase the overall plumbing cost. That is why it is recommended to outsource plumbing cost estimator services and safeguard your project budget.

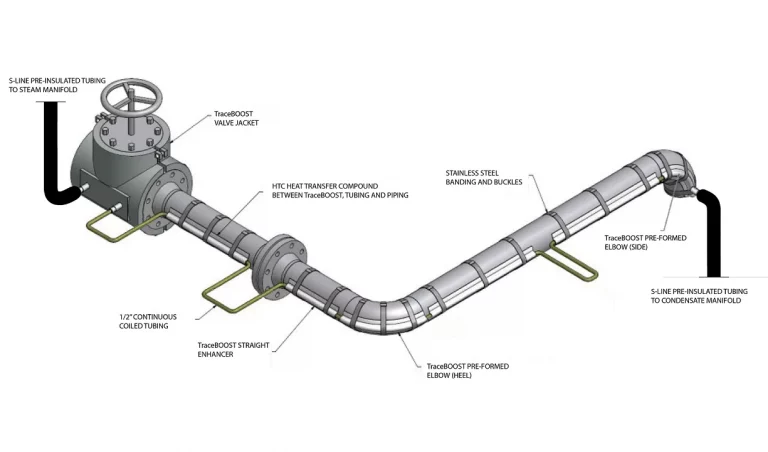

5. Additional System Components

Gas line installations often include additional components that must be factored into the final budget. For example, valves and shut-offs are important materials of the gas line in case of any leak. You may expect a $10–$25 expense to install it. In addition to that, leak detection systems are also installed in the larger systems.

Let’s Consider an Example!

-

Materials (Pipe, Valves, Connectors): $15–$25 per linear foot

-

Labor (Installation and Testing): $75–$150 per hour

-

Permits and Inspection: $100–$300 total

-

Excavation (if applicable): $8 per foot

-

System Testing and Safety Checks: $100–$200

-

Overhead and Profit: 10%–20%

You should budget approximately $2,000 to $5,000 for complete gas line installation. But be sure to review all contributing factors shared above to avoid hidden expenses. The most crucial thing is the initial planning of the project so make sure to not miss even a single project information!

Why Accuracy Matters When Planning Gas Line Systems for New Builds?

Gas leaks can lead to explosions, which is why precise sizing and testing are important. Accurate estimation is vital as it ensures that all components like pressure regulators and valves are correctly installed. These precautions reduce safety risks to a large extent.

In any construction project, some unexpected expenditures can always increase the total cost of the project. In large commercial or industrial projects, gas plumbing often represents a significant portion of mechanical, electrical, and plumbing costs.

Planning the cost of a gas system in a new build is a challenging task, which is why you need to be very careful while evaluating the required project materials. The installation of gas plumbing systems is related to building safety. That is why you need to be super accurate so that you may prevent over-budgeting.

Local building codes are the rules set by the government to ensure the structural health of the building. Hence, specific materials and installation methods are required for gas plumbing. You can fail in inspection if cheap or non-compliant material is used. It can cause delays in the project and increase the cost of reconstruction.

Resource allocation is important to ensure that the process is done smoothly and efficiently. Accurate estimates allow you to efficiently use the resources and materials on the site as needed. It is particularly important in commercial and industrial projects because delays in projects can impact operational timelines.

NOW ARE YOU PREPARED ENOUGH TO TACKLE GAS PLUMBING COSTS FOR NEW CONSTRUCTION? JUST MAKE SURE TO CHOOSE THE RIGHT APPROACH FOR YOUR NEEDS AND GET THE MOST RELIABLE COST ESTIMATES!

Final Words!

In short, to estimate gas plumbing costs for new construction, you need to be careful while considering project requirements. We have discussed all the major expenses and factors that are covered in the gas plumbing projects. If you rely on professional estimating companies, you will never end up over- or under-budgeting. For this reason, it is recommended to take professional opinions because you will get precise calculations.