How to Estimate Piping and Pumps for HVAC in the U.S.: Costs, Methods, and Tips (2025 Guide)

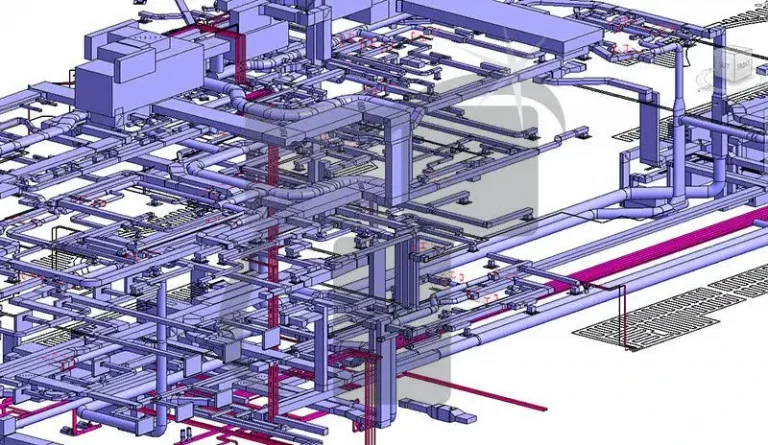

In an HVAC project, costing is a significant part because it comprises various components, including HVAC Piping and Pump Estimation. To estimate piping and pumps, you follow a certain procedure. Luckily, this article provides you with the most recent (2025) information on costs, estimation methods, rebates, and valuable tips to ensure accuracy in your estimates.

Know all about how to estimate HVAC piping and pumps in the United States with confidence!

Piping Costs in an HVAC System

First of all, it is important to mention that the costs of pipe in an HVAC system are determined by the following constituents:

Material Type

Commonly, there are three types of materials, such as:

- Copper (about $4.00 – $12.00 per linear foot in 2025 U.S. markets)

- Steel (carbon or galvanized, roughly $3.00 – $10.00 depending on diameter and finish)

- PEX (about $0.50 – $4.00, depending on size and type)

Remember: insulation, fittings, and hangers can add significant cost.

Pipe Size and System Layout Complexity

A larger pipe means that the cost will also increase; for example, a 6-inch copper pipe will be more expensive compared to a 3-inch pipe. If a system’s layout is complex—tight spaces, long runs, or numerous bends—labor costs climb.

Installation Constraints

Easy installation conditions will be cheaper compared to difficult ones. For instance, limited access or installation at heights will increase labor hours, require safety equipment, and trigger additional permit considerations.

Pump Costs (HVAC Related)

Because “pump” can mean different things in HVAC, clarify whether you mean circulating pumps or heat pump systems for heating/cooling.

- Mini-split or single-zone air-source heat pumps: roughly $1,500 – $5,000 installed.

- Multi-zone ductless or ducted air-source systems: typically $6,000 – $18,000 depending on zones and complexity.

- Geothermal heat pump systems: about $12,000 – $30,000+, depending on loop type and drilling requirements.

Cost Influencing Factors

- Type of Pump/System: air-source vs. geothermal vs. simple circulation pumps.

- Size and Model: higher-capacity or newer high-efficiency models cost more.

- Efficiency Ratings (SEER2 / HSPF2): higher ratings raise upfront cost but lower operating cost and may qualify for rebates.

- Installation Complexity: difficult site conditions, long piping runs, and specialty equipment drive labor costs higher.

- Regional Material and Labor Inflation: U.S. copper and steel prices have risen 15–35 % since 2023 due to tariffs and supply constraints.

Incentives & Rebates (2025 Update):

Federal and state programs under the Inflation Reduction Act can significantly reduce net costs for high-efficiency heat pumps. Homeowners and contractors should check the U.S. Department of Energy’s rebate and tax credit page for current opportunities.

Different Strategies for Estimating an HVAC System

There are plenty of estimation methods used by Piping Estimating Services. It all depends on the project requirements and specifications:

- Square Footage Estimation: ideal for early budgeting.

- Resource-Based Estimation: a detailed breakdown of materials, labor, and equipment for a more accurate total.

- Historical Data Estimation: compares prices, site conditions, and complexity with similar past projects.

- Parametric/Performance-Based Estimation: uses performance parameters such as required flow rates, expected loads, and zoning to derive precise costs.

Proactive Tips for HVAC Piping Estimation

Follow these steps for accurate HVAC piping estimation:

- Review Codes and Standards Early: Confirm compliance with ASHRAE, local plumbing, and mechanical codes to avoid costly redesigns.

- Drawings Dissection: Analyze drawings to understand the system layout and total piping needed.

- Piping Takeoff: Use estimating software such as Fast Duct or similar to measure exact quantities directly from the drawings.

- Materials Costing: Research up-to-date material prices using tools like RSMeans or current supplier quotes.

- Labor Appraisal: Evaluate required labor hours based on:

- Site conditions

- Installation method

- Productivity and union vs. non-union wage rates

- Site conditions

Ending Remarks

Working on an HVAC project can be exhausting due to its many intricacies. Without proper knowledge, HVAC Piping and Pump Estimation can lead to financial loss. By following updated cost data, understanding rebates, and applying professional estimation methods, you can create accurate budgets and avoid overruns.