Understanding SMACNA Standards in Duct Estimating

Any professional involved in working with ducting has likely come across the SMACNA Standards for Ductwork. These standards provide technical guidelines and develop manuals that are globally recognized in the construction industry. It is important to mention that these standards are authorized by the American National Standards Institute, which is an official body that outlines standards.

What is SMACNA and Why is It Important?

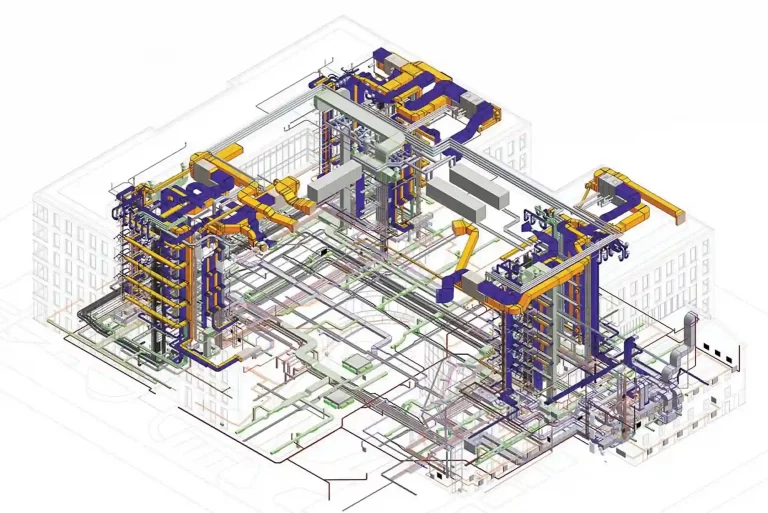

SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association) is an internationally recognized authority in the HVAC industry. Its standards cover everything from duct design and fabrication to installation, ensuring systems are safe, efficient, and compliant with building codes. Adhering to SMACNA guidelines helps maintain quality control, reduces energy loss, and enhances overall system performance.

This article will discuss the SMACNA standards related to ductwork and how these standards help in the estimation process of ducting. So let us begin our discussion!

Concerning SMACNA Standards for Ductwork

The standards set by SMACNA for ductwork encompass air conditioning and sheet metal. These standards address multiple aspects such as design, construction, installation, and performance. All of these collectively help in the accurate estimation of ductwork.

Additionally, SMACNA standards also cover areas such as leakage classification, pressure classes, and material selection to ensure durability and system integrity. Let’s go through the SMACNA standards for duct designs.

SMA Guidelines for a Duct Design Process

In this section, we are going to discuss how SMACNA standards streamline the process of duct design.

A System’s Arrangement

For effectively designing a duct, it is important to assess a system’s arrangement. This is because a system’s arrangement determines how air will circulate throughout the building. For this, you have to consider the following:

- The first thing you need to consider is the dimensions of a room. The bigger a room is, the larger ducts it will require

- Each section of a building requires a different flow of air, and this must also be taken into control

- It is also important to ensure that there are no obstacles in the passage of a duct, as this can compromise the design of a duct.

Moreover, SMACNA suggests considering factors such as duct length, number of fittings, and friction loss during design to ensure optimal performance and energy efficiency.

After having a thorough discussion about SMACNA duct design standards, let’s have a look at the construction standards for ducts by SMACNA.

SMACNA Duct Construction Standards

Besides design, SMACNA also provides standards on how ducts must be constructed. The standards that are going to be discussed in this article not only ensure that the right materials are chosen, but they also ensure that the required safety and performance benchmarks are met.

Material Selection for Ductwork

SMACNA guidelines specify materials such as galvanized steel, aluminum, and stainless steel based on environmental conditions. For example, stainless steel is often used in areas prone to high humidity or chemical exposure to prevent corrosion.

SMACNA covers almost every aspect of ductwork, thus providing standards for each of them, including Sheet Metal Fabrication Standards and duct sizing. Let’s discuss them separately!

Sheet Metal Fabrication Standards

These standards assure that the sheet metal used in ductwork is of high quality, safe, and facilitates the manufacturing of a reliable and durable product.

Duct Sizing

SMACNA provides guidelines regarding duct sizing as well as formulas. These formulas consider the velocity of airflow, loss due to friction, and how much space a duct will take. All of this will ensure that the ducts are precisely sized and there will be a smoother airflow.

Example Formula for Duct Sizing:

SMACNA uses the Equal Friction Method and Velocity Reduction Method. For instance, if airflow is 1,200 CFM at a friction rate of 0.08 in. w.g. per 100 ft, the duct size might be approximately 18″x10″.

For a step-by-step calculation, see our detailed guide on Calculating HVAC Duct Size

SMACNA Standards for Residential and Commercial Buildings

SMACNA has also set different sizing standards for different levels of projects. For instance, SMACNA standards for residential buildings are determined by the required air for a particular area. In a residential building, a standard bedroom requires 200 – 500 CFM (Cubic Feet per Minute), while a larger room might require up to 500 – 1000 CFM.

This means that the design and sizing of the duct for a residential building will be lower as compared to a commercial building.

As in commercial buildings, certain sets of requirements must be considered, such as the building type, number of occupants, and how much is the usage.

After having a thorough discussion about design and sizing, these standards also help in duct estimating. Here’s how these standards are helpful!

How SMACNA Standards Help in Duct Estimating Services

By following these standards, accuracy is assured in delivering Duct Estimating Services. The standards set by SMACNA are not just theoretical; these guidelines offer a practical solution for various types of problems. By following them, you will get a correct design and precise sizing, and this will greatly help in obtaining accurate duct estimates. These standards assure that every little detail is covered in terms, thus leading to timely Estimating services for ductwork.

For example, when preparing a duct takeoff, SMACNA tables for metal gauges and pressure classifications help estimators determine material weights and cost. This reduces guesswork and ensures bids remain competitive while meeting compliance.

Installation Guidelines by SMACNA

When everything is covered, it is time to start the installation process. SMACNA provides certain recommendations for installing an HVAC system. They are as follows:

- Ensure that a consistent and overlapping seal is applied over duct joints to prevent any air leakage

- Adequate duct insulation must be done to avoid any heat loss and also reduce noise

- Incorporating vibration dampeners to eliminate the issue of duct vibration.

TRANSFORM YOUR DUCTWORK TODAY WITH THIS COMPREHENSIVE GUIDE ABOUT SMACNA STANDARDS!

Final Verdict

Dealing with an HVAC system can seem complex. However, by following SMACNA Standards for Ductwork, the process becomes easier as well as accurate. These extensive standards cover everything related to ductwork. From guidelines on how to design a duct to how to acquire precise sizing of the ducts, and that’s not it. These standards also provide recommendations on how to ensure an effective installation process. Collectively, this will make sure that an HVAC system functions properly and is dependable. In this article, we have covered essential SMACNA standards that will help you in accurately estimating how much duct you might require for your project.

FAQ’s

What does SMACNA stand for?

SMACNA stands for Sheet Metal and Air Conditioning Contractors’ National Association. It is an internationally recognized body that develops technical standards for ductwork, HVAC systems, and related sheet metal applications.

Are SMACNA standards mandatory?

While SMACNA standards are not always legally binding, they are widely accepted as the industry benchmark. In many cases, local building codes and project specifications require compliance with SMACNA guidelines for safety and performance.

Why are SMACNA standards important for ductwork?

SMACNA standards ensure that duct systems are designed and constructed properly, minimizing energy loss, preventing leakage, and meeting airflow requirements. This leads to better efficiency, lower costs, and improved indoor air quality.

How do SMACNA standards affect duct estimating?

By following SMACNA guidelines, estimators can accurately determine material quantities, labor costs, and project timelines. This eliminates guesswork and helps deliver competitive, precise bids for ductwork projects.

Do SMACNA standards differ for residential and commercial buildings?

Yes, SMACNA provides separate guidelines for residential and commercial projects. Factors such as CFM requirements, pressure classes, and material thickness vary depending on the size and purpose of the building.