What Are the Key Materials Used in Pipework Insulation?

The importance of Pipework Insulation in plumbing systems cannot be denied. They are a critical component of every building. We only pay attention to it when something goes wrong.

The main purpose of insulation is to regulate the temperature of hot and cold water passing through these pipes. It functions as a cloak between the surroundings and the pipe.

Uses of Pipework Insulation

Let’s further explore the uses of pipework insulation.

- Minimising heat loss or gain

- Increasing energy efficiency

- Combating corrosion and moisture by controlling condensation

- Increasing the lifespan of the system

- Protection from freezing of pipes

- Reducing unpleasant noises from the pipe

- Provide structural stability to the pipes

LEARN ABOUT THE PROS AND CONS OF VARIOUS MATERIALS THAT CAN BE USED FOR PIPING INSULATION AND GAIN INSIGHTS INTO THEIR CHARACTERISTICS AND PROPERTIES.

Types of Materials Used for Pipework Insulation

There are many options for Pipework Insulation, each having its advantages and disadvantages. Here, we uncover these types in detail.

Foam

A relatively new form of insulation that has been becoming popular. Foam can be used for insulation by spraying it directly on the pipe. After some time it hardens forming a protective layer around the pipe. It is a widely used material for cold-temperature pipes as it forms well with cold. Other than that, it is also used for PVC and copper pipes.

Pros

- Easy to install

- Resistant to mould

- Flexible

- Durable and long-lasting

- Lightweight

Cons

- Contributes to climate change

- May shrink over time

- Can be damaged by insects or rodents

- Vulnerable to UV exposure

Further Types

Common types of foaming materials include

- Polyisocyanurate (PIR): Relatively affordable, good thermal and moisture resistance, versatile, more accessible.

- Phenolic: Expensive, better thermal and moisture resistance than PIR, resistant to fire, less accessible.

Rubber

Versatile material for pipework insulation. Rubber insulation is commonly used for pipes in tiny spaces or at difficult angles. That is because it can be moulded into any shape or form. It can be used for iron, PVC and copper pipes. It can control lots of condensation.

Pros

- Resistant to moulds

- Flexible to use

- Highly durable

- Excellent moisture resistance

Cons

- Flammable when exposed to fire

- May require a chemical-resistant coating

- Expensive

Further Types

There are two main types of rubber used for insulating pipes:

- Nitrile Rubber (NBR): Temperature resistance up to 120°C, higher compression, good chemical resistance.

- EPDM Rubber: Temperature resistance up to 150°C, less compression, resistant to ozone and UV radiations but vulnerable to oils and fuels.

Fibreglass

It is made from fine glass fibres which are weaved together and then wrapped around the pipe. Fibreglass pipework insulation offers resistance to both cold and hot temperatures. Moreover, it is fire resistant as well.

Pros

- Affordable

- Resistant to corrosion

- Low thermal conductivity

Cons

- Not suitable for extreme temperature

- Not Flexible

- Irritating to skin and eyes

- Can lose insulation properties due to the absorption of water

Mineral Wool

A type of pipework insulation that is made out of rock fibres. Rocks such as stones and silica are melted at high temperatures and then turned into fibres. It is an effective thermal insulation material widely used for pipes. It is perfect for high-temperature environmental conditions due to its ability to withstand extremely hot temperatures.

Pros

- It is non combustible

- Reduces noise by absorbing sound

- Improved energy efficiency

- Resilient and durable

- Can withstand temperature Increasing 1,000º C

Cons

- More expensive

- Less accessible

- Lung irritation

- Climatic concerts

Aluminium Foil

When wrapped around pipes, it can form reflective insulation. resistant to sunlight thus keeping the pipes cool. It is mostly used for cold water regulation as compared to heat. It is also good at controlling condensation.

Pros

- Can keep the sun away due to resistant properties

- Easy to install

- No water absorption

- Resistant to moulds

Cons

- Not as effective as other insulators in heat regulation

What Material is Best For You?

When it comes to choosing the best material, it all comes down to your requirements. Factors that you should consider are environmental conditions, thickness of pipes, placement of pipes, temperature range etc.

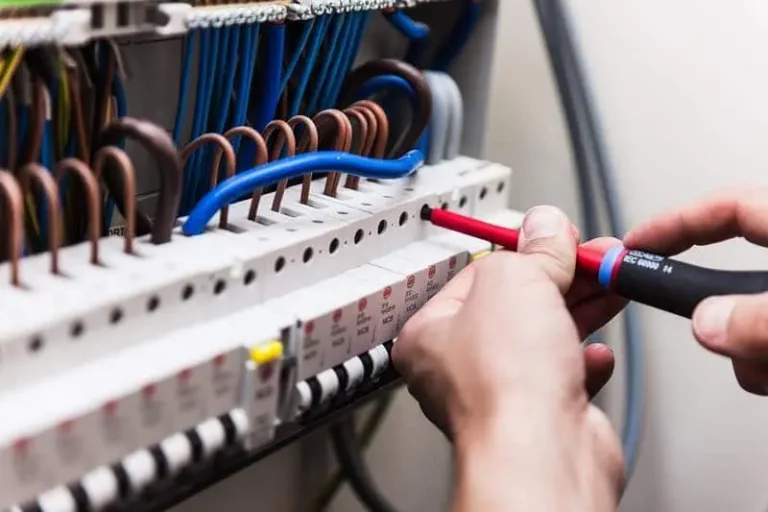

You also need to consider the needs of your building and your budget. If you are worried about the cost then there’s a simple solution. Piping Estimating Services can create an accurate cost budget based on your requirements. The budget is tailored specifically for your needs by incorporating cost-effective strategies. It can not only help to avoid unnecessary expenses but also aid the decision-making process.

RELAY ON A COST-ESTIMATING SERVICE TO MANAGE YOUR FINANCES AND MAKE SURE THAT YOUR PIPING INSULATION IS COST-EFFECTIVE AND FUNCTIONS WELL!

Benefits of Estimating Services

The following are the Benefits of Estimating Services:

- A precise cost budget

- Cost-effective solutions

- Access to advanced tools

- Improved decision making

- Effective allocation of resources

- Better cash flow

- Assessment of financial risk factors

Final Words

The piping system is a vital part of the building so there should be no compromise on it. It increases the building’s life but ensures an effective plumbing system. It is crucial to evaluate your own needs first before making any decision. Don’t be hesitant to ask for professional help! As there are several choices for piping insulation, it is better to collaborate with experts rather than make a wrong costly decision.